Redefining Product Decoration

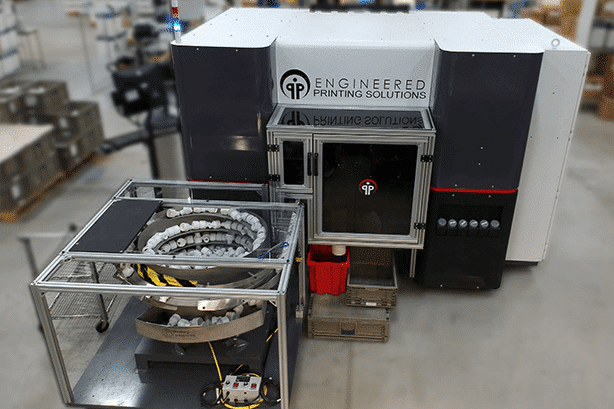

Since 1985, Engineered Printing Solutions has worked with market leaders to build industrial print machinery with custom automation for product-line integration.

Explore Our Products & Custom Solutions

Not sure where to get started?

Tell us what you’re looking for by answering a few quick questions about your requirements.

Our Products

Explore by Application

Lorem ipsum dolor sit amet consectetur adipiscing elit semper dalar elementum tempus hac tellus libero accumsan. Not sure where to start? Let’s work on this together—Contact Us.

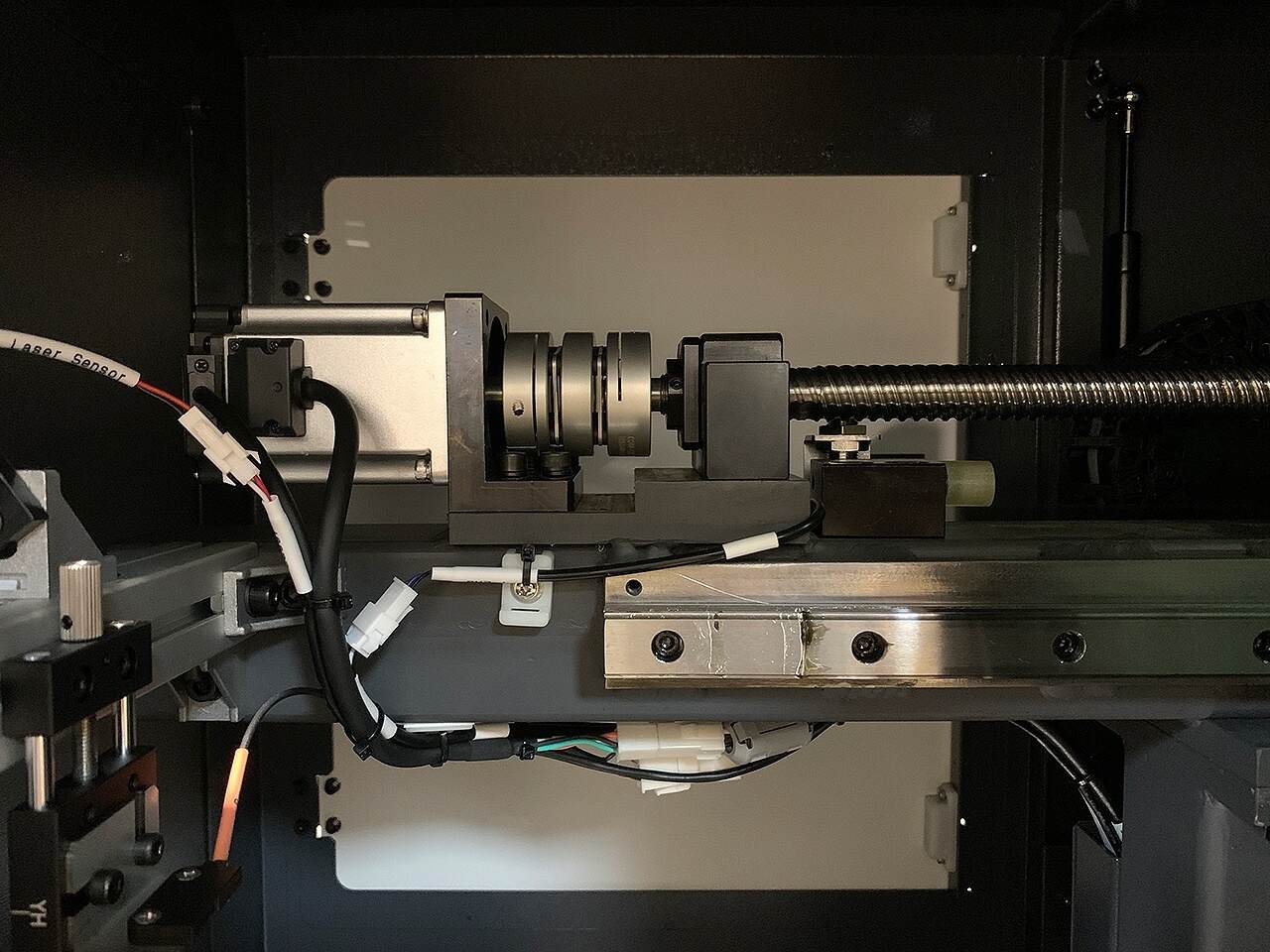

Custom Engineering & Automation

Lorem ipsum dolor sit amet consectetur adipiscing elit volutpat gravida malesuada quam commodo id integer nam.

What’s New

Lorem ipsum dolor sit amet consectetur adipiscing elit volutpat gravida malesuada quam commodo id integer nam.