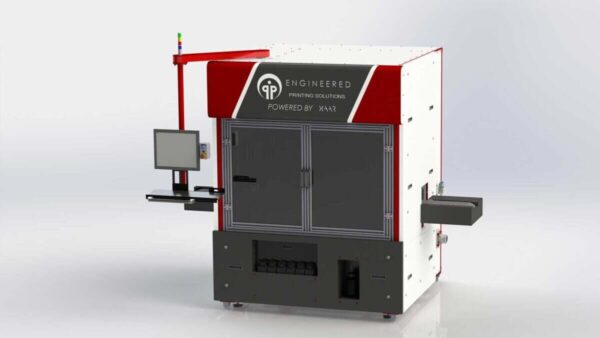

XDLT High-Speed Direct-to-Object Digital UV Industrial Automated Single Pass Inkjet Printer

High Speed Direct-to Shape Printing Converorized Linear Pinter The XDLT represents a significant leap forward in decorating equipment, strategically designed to bridge the production gap that exists in the industry.

Ready to move forward or have questions?

By integrating the reliability and high performance of continuous printing with Through-flow print head technology, it offers a seamless solution for businesses seeking enhanced efficiency and versatility in their printing processes.

What sets the XDLT apart is not just its advanced technology, but also its lighter and more nimble design. This combination of features ensures that the XDLT is not only capable of delivering top-notch results but also offers flexibility and ease of use, making it a valuable asset for businesses of all sizes.

Positioned strategically between existing UV flatbed and high-speed custom single pass lineups, the XDLT strikes a perfect balance in terms of both price and capability. It fills a crucial void in the market, catering to the needs of businesses that require high-quality printing solutions without breaking the bank.

With the XDLT, printing becomes not just a task but an experience. Its innovative features and unparalleled performance are poised to revolutionize the way printing is done, empowering businesses to achieve new levels of productivity and creativity.

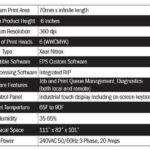

| Power | 240VAC 50/60Hz 3-Phase, 20 Amps |

|---|---|

| Physical Space | 111” x 82” x 101” |

| Humidity | 35-65% |

| Ambient Temperature | 65F to 90F |

| Control Panel | Industrial touch display including on-screen keyboard |

| Software Features | Job and Print Queue Management, Diagnostics (both local and remote) |

| Image Processing Software | Integrated RIP |

| Compatible Software | EPS Custom Software |

| Print Head Type | Xaar Nitrox |

| Number of Print Heads | 6 |

| Printable Area Width | |

| Maximum Product Height | 6" |

| Printable Area Length | |

| Maximum Resolution | 360 dpi |

- Xaar Nitrox Print heads (WWCMYK)XDLT Specs

- GIS print electronics for static data

- CIMS II 450 ink management system

- Integration Technologies UV Pin and Cure

- Welded steel frame

- Max printable product size (6in x 8in)(HxW)

- Standard conveyor design (14in/s)

- Manual Z and Cross Track adjustment

- Maintenance Waste Tray

- Ventilation hookup

- Crash Detect included for protection of printhead

- Beckhoff Industrial PC with standard HMI interface

- Standard customer interface connector for I/O and E-Stop circuitry

- Manual print axis with built in fine adjustment for Crosstrack.

- Can be populated with up to 6 colors (WW-CMYK standard).

- Liquid UV curable inks.

- Self-contained ink system with bulk refill.

- Product heights up to 150mm.

- Fume extraction ready.

- Job & Print Queue Management for local and remote diagnostics.

- Beckhoff Industrial PC with standard HMI interface.

- Power Requirements: 240VAC, 50/60Hz, 20A

- Options: Custom part fixturing.

Product Add-Ons

Here to Answer Your Questions

Frequently Asked Questions

Whether you’re a new customer or an existing experienced customer, we are here to support you with your ordering and quoting needs.